Understanding Wind Turbine Efficiency: Factors and Improvements

Building a small-scale wind turbine is a rewarding project, offering a hands-on introduction to renewable energy. However, simply building a turbine isn’t enough; maximizing its efficiency is key to generating useful power. This article will delve into the factors affecting wind turbine efficiency and explore ways to improve your DIY wind power system. Before you dive into optimizing efficiency, you might want to consider the core components involved; for instance, understanding how to build your own alternator is fundamental to the process - a topic explored in detail in DIY Wind Turbine Generator: Build Your Own Alternator.

What is Wind Turbine Efficiency?

Wind turbine efficiency refers to the percentage of wind energy converted into usable electricity. It’s not a simple calculation and rarely reaches 100% due to various losses. Theoretical maximum efficiency, known as the Betz limit, is around 59.3%. Real-world turbines, especially small-scale DIY models, typically operate at significantly lower efficiencies, often in the 20-40% range.

Factors Affecting Wind Turbine Efficiency

Several factors contribute to how efficiently your wind turbine operates. Understanding these factors is the first step in optimizing your design.

Wind Speed

The most crucial factor is wind speed. Power in the wind is proportional to the cube of the wind speed (P ∝ v³). This means a small increase in wind speed dramatically increases the power available. A turbine needs to be placed in a location with consistent and adequate wind speeds – avoid areas blocked by trees or buildings. Accurate measurement of wind speed is vital, and often requires a dedicated anemometer – a consideration before the build even begins.

Blade Design

Blade shape, size, and the number of blades play a significant role. Longer blades sweep a larger area, capturing more wind. However, longer blades also experience greater stress and are more difficult to control. The shape of the blade (airfoil) is critical for maximizing lift and minimizing drag. Simpler, smaller-scale turbines often use a less-optimized airfoil, impacting efficiency. Experimentation with blade profile can lead to surprising gains. The number of blades, while often standardized to three, can also have a significant impact on efficiency and overall turbine behavior. A well-designed blade can be the difference between a functional prototype and a truly efficient power generator.

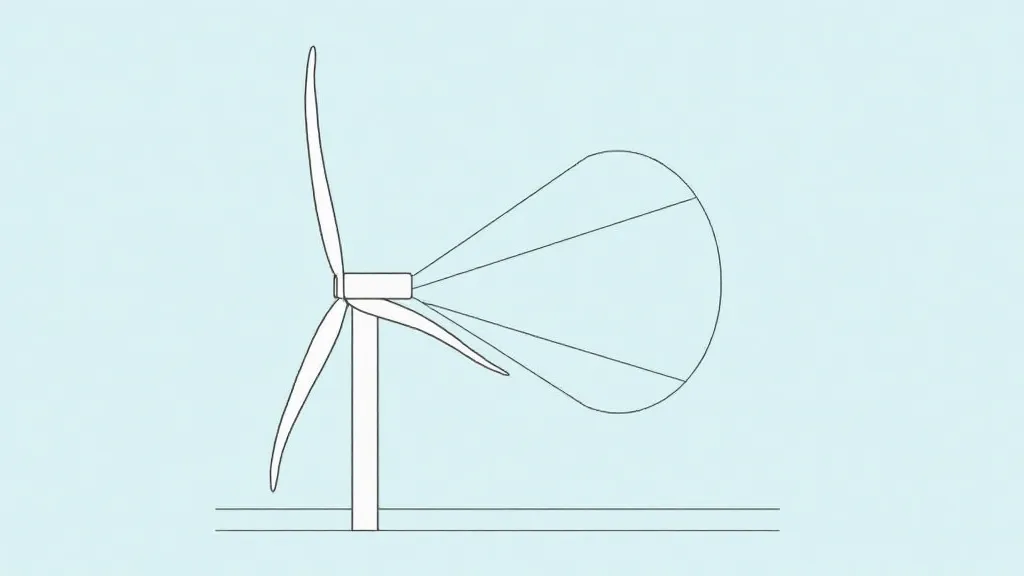

Rotor Diameter

The rotor diameter, the overall width of the blades, directly influences the amount of wind the turbine can capture. A larger diameter means a larger swept area. However, size is constrained by structural integrity and the mechanical power available to rotate the turbine. Finding the right balance between rotor diameter and structural demands is a key challenge in DIY wind turbine construction.

Generator Efficiency

The generator converts mechanical energy from the blades into electrical energy. The generator’s efficiency is itself a limiting factor. Low-quality generators or those mismatched to the turbine’s rotational speed can significantly reduce overall efficiency. Choosing the right generator is paramount; a mismatch can lead to frustratingly low power output. As you explore generator selection, consider the complexities of constructing your own; this process necessitates a deep understanding of alternator principles, topics covered in DIY Wind Turbine Generator: Build Your Own Alternator.

Gearbox (If Applicable)

Some designs incorporate a gearbox to match the turbine’s rotational speed to the generator's optimal speed. Gearboxes introduce friction losses, which reduce efficiency, so their use requires careful consideration. While gearboxes can theoretically improve efficiency by allowing the generator to operate at its optimal RPM, the added complexity and frictional losses often outweigh the benefits in small-scale DIY projects. Direct-drive systems, where the turbine blades are directly connected to the generator, are often simpler and more efficient for DIY builds.

Improving Wind Turbine Efficiency

Here are some strategies to improve the efficiency of your small-scale wind turbine.

Location, Location, Location

Prioritize placement! Find a location with consistent, unobstructed wind. Consider the local terrain and prevailing wind patterns. Wind resource assessment is a critical first step; simply choosing a spot that *looks* windy isn't enough. Consider using tools like wind maps and performing on-site measurements to determine the optimal location for your turbine.

Optimize Blade Design

While complex airfoil designs can be challenging for DIY projects, even small improvements in blade shape can make a difference. Research basic airfoil principles and experiment with different shapes. Ensure blades are balanced to minimize vibration and stress. Blade balancing is a crucial step often overlooked; even slight imbalances can lead to significant performance losses and premature wear.

Use a High-Efficiency Generator

Invest in a generator specifically designed for wind turbine applications, and choose one that matches the expected rotational speed of your turbine. Permanent magnet generators (PMGs) are often a good choice. Consider the trade-offs between different generator types, as each has its own advantages and disadvantages in terms of efficiency, cost, and complexity. Custom-built generators offer the ultimate in optimization, but require advanced skills and resources.

Reduce Friction

Minimize friction in all moving parts – bearings, gears (if used), and the hub. Regular lubrication is essential. The type of lubricant used also matters; specialized lubricants designed for high-speed bearings can significantly reduce friction and extend the lifespan of the turbine.

Consider a Tail Vane

A tail vane automatically aligns the turbine into the wind, maximizing energy capture. This is particularly important for smaller turbines that may be more easily deflected by gusts. Proper tail vane design is also important; it needs to be lightweight yet strong enough to withstand gusts and changes in wind direction. The efficiency gains from a well-designed tail vane can be substantial.

Match Turbine Size to Wind Conditions

A larger turbine might seem better, but if your location has primarily low wind speeds, a smaller, lighter turbine will perform better. The “sweet spot” for turbine size depends on the specific wind resource available at the installation site. Understanding the local wind profile is crucial for making informed decisions about turbine size and design.

Beyond Single Turbine Optimization: System Integration and Regulations

Maximizing wind turbine efficiency doesn't end with the turbine itself. Consider the entire system, including the charge controller, batteries (if applicable), and inverter. An inefficient charge controller can negate the benefits of a highly efficient turbine. Furthermore, be aware of the legal and regulatory aspects of small-scale wind turbines – permits, zoning restrictions, and grid interconnection requirements can all impact the viability of your project. Navigating these regulations can be complex and time-consuming. Before embarking on a DIY wind turbine project, it’s wise to investigate these local ordinances, details about which can be found in resources like Legal and Regulatory Aspects of Small-Scale Wind Turbines.

Troubleshooting Common Efficiency Problems

Even with careful planning and optimization, wind turbines can experience efficiency problems. Excessive noise can be a symptom of underlying mechanical issues, such as blade imbalances or bearing failures. Similarly, unexpected temperature increases in the generator can indicate overloading or inefficient operation. Regularly monitoring these parameters can help identify and address problems before they escalate. Furthermore, you may want to explore construction kits as an alternative, with details of benefits and drawbacks easily accessible at DIY Wind Turbine Kits: Pros and Cons Compared to Scratch Builds.

Conclusion

Building a wind turbine is a fantastic learning experience. By understanding the factors that influence efficiency and implementing strategies for improvement, you can maximize your power generation and gain a deeper appreciation for the challenges and rewards of renewable energy. Experimentation and careful observation are key to success. Remember to continually monitor your turbine's performance and make adjustments as needed. The journey to building an efficient wind turbine is often iterative, requiring patience, persistence, and a willingness to learn from mistakes.