Wind Turbine Maintenance: Extending the Lifespan of Your Turbine

Building your own small-scale wind turbine is a rewarding project, offering a sustainable way to generate electricity. However, the work doesn't stop after the build! Regular maintenance is absolutely critical to maximizing your turbine's performance and extending its lifespan. Neglecting upkeep can lead to decreased efficiency, premature failures, and potentially dangerous situations. This article provides a practical maintenance schedule you can follow to keep your DIY wind turbine running smoothly. Before diving into maintenance, it's helpful to have a solid understanding of wind turbine basics, covering fundamental components and their functions.

Why is Maintenance So Important?

Just like any mechanical device, wind turbines experience wear and tear. Constant rotation, exposure to the elements, and varying loads all contribute to degradation. Consistent maintenance addresses these issues proactively, preventing small problems from escalating into major, costly repairs or replacements. A well-maintained turbine produces more power, operates more safely, and lasts longer. Consider the effort you put into the build itself; investing time in regular maintenance is an extension of that dedication, ensuring a continued return on your investment.

A Seasonal Maintenance Schedule

The following schedule is a guideline; adjust it based on your turbine’s design, location, and usage. It's broken down by season and frequency. Always disconnect the turbine from the electrical system before performing any maintenance. This is non-negotiable and vital for your safety.

Spring (Pre-Summer - Monthly Check)

- Visual Inspection: Carefully examine the blades, tower, and all connections for cracks, rust, or any signs of damage. Pay close attention to blade tips – these are common areas for wear. Even subtle changes can indicate underlying issues.

- Blade Balance Check: Even slight imbalances can cause vibrations and reduce efficiency. Re-check and adjust blade weights if necessary. Blade imbalances can significantly impact turbine performance and longevity.

- Tower Inspection: Assess the tower’s foundation and structure. Look for any signs of settling or corrosion. A stable tower is essential for safe and efficient operation.

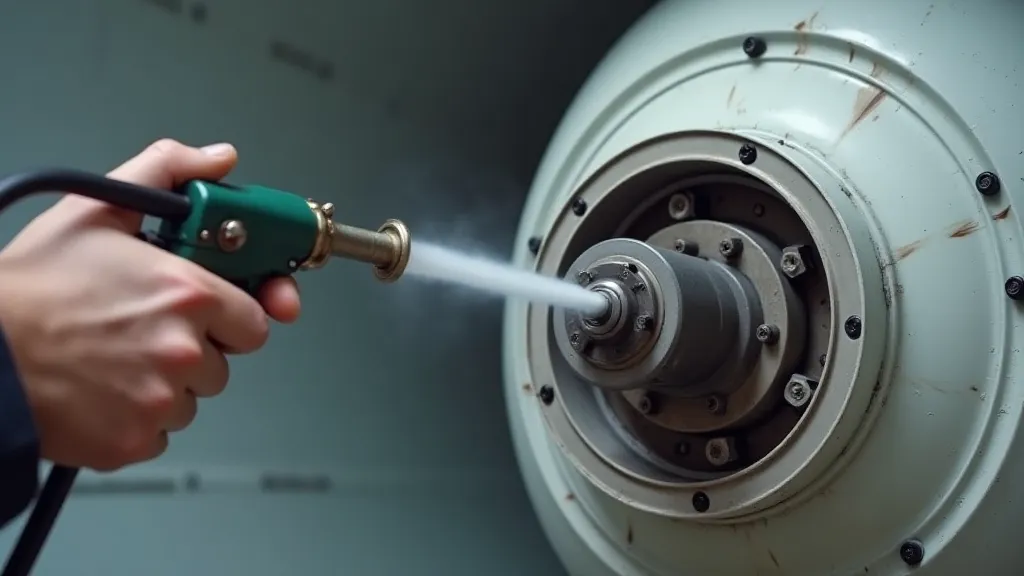

- Bearing Lubrication: Lubricate all bearings according to the manufacturer’s recommendations (or using appropriate grease for DIY builds). Proper lubrication minimizes friction and extends bearing life.

- Wiring Check: Inspect all electrical wiring for fraying, damage, or loose connections. Electrical safety is paramount, and damaged wiring poses a serious hazard.

Summer (Peak Generation - Bi-Monthly Check)

- All Spring checks (repeat)

- Generator Performance: Monitor the generator's output voltage and current. Any significant deviations from expected values could indicate a problem. Regular monitoring helps identify potential generator issues early on.

- Yaw System Check (if applicable): If your turbine has a yaw system to keep it facing the wind, ensure it’s operating correctly. A functioning yaw system maximizes energy capture.

- Cleanliness: Clean any accumulated dirt or debris from the blades and generator. Accumulated debris reduces efficiency and can contribute to wear.

Autumn (Pre-Winter - Monthly Check)

- All Spring and Summer checks (repeat)

- Bolt Tightness: Check and tighten all bolts and fasteners. Vibrations can loosen these over time. Maintaining proper bolt tightness prevents catastrophic failures.

- Weatherproofing: Ensure all weatherproofing seals and connections are intact and functioning properly, especially critical for preventing ice buildup in colder climates. Protecting the turbine from the elements is crucial for long-term reliability.

Winter (Cold Weather - Quarterly Check)

- All previous checks (repeat)

- Ice Buildup Prevention: If you live in an area with ice, consider applying a de-icing agent to the blades (check compatibility with your blade material first). Ice accumulation can severely impact turbine operation and safety.

- Gearbox Lubrication (if applicable): If your turbine utilizes a gearbox, ensure it is adequately lubricated. Gearbox failure is a common and costly repair; proper lubrication is key to preventing it.

- Overall System Assessment: Perform a more thorough assessment of the entire system, looking for any signs of wear or potential problems. A comprehensive assessment helps identify subtle issues that might otherwise be missed.

Tools and Materials for Maintenance

Choosing the right tools is just as important as following the maintenance schedule. Improper tools can damage components and compromise safety.

- Wrench set

- Screwdriver set

- Grease gun

- Lubricant (appropriate for your turbine’s bearings and gearbox)

- Electrical multimeter

- Safety glasses

- Gloves

- Torque wrench (for critical fasteners)

- Blade balancing kit (if adjustments are needed)

- Cleaning supplies (appropriate for blade materials)

Safety First!

Working at heights is inherently dangerous. Always follow proper safety procedures, including wearing appropriate personal protective equipment (PPE) and having a second person present. If you’re not comfortable working at heights or handling electrical equipment, consider hiring a qualified professional. Many people are drawn to DIY wind turbines for their sustainability, but safety should always be the top priority. Furthermore, understanding the legal and regulatory aspects of wind turbine operation can be critical. You may wish to investigate local ordinances and permitting requirements before construction and operation. For those new to this field, exploring options like DIY wind turbine kits can offer a simplified, safer path to harnessing wind energy.

Conclusion

Regular maintenance is a small investment that pays significant dividends in terms of performance, longevity, and safety. By following this schedule and being proactive about identifying and addressing potential problems, you can ensure your DIY wind turbine continues to generate clean, renewable energy for years to come. Remember that consistent monitoring and preventative measures extend the lifespan and maximize the return on your wind turbine project, making it a truly sustainable and rewarding endeavor.