Sizing Your Wind Turbine: Calculating Power Needs and Turbine Capacity

Building a small-scale wind turbine is a rewarding project, but getting it right starts with careful planning. One of the most crucial aspects is sizing the turbine to meet your power needs. A turbine that’s too small won't generate enough electricity, while one that’s too large will be inefficient and potentially damaging. This article breaks down the calculations and considerations involved in determining the right wind turbine size for your application.

1. Understanding Your Power Needs

Before you even think about turbines, you need to figure out how much electricity you use or plan to use. Here's a breakdown:

- Identify Appliances/Loads: List everything you want the wind turbine to power. This could include lights, refrigerators, water pumps, computers, etc.

- Determine Wattage: Find the wattage of each appliance. This is usually printed on a label on the device.

- Calculate Daily Energy Consumption (Watt-hours): Multiply the wattage of each appliance by the number of hours you use it per day. For example, a 60W light bulb used for 4 hours a day consumes 240 Wh (60W * 4h).

- Sum Daily Energy Needs: Add up the daily energy consumption (in watt-hours) for all appliances. This gives you your total daily energy need.

- Factor in Peak Demand: Consider the highest wattage you're likely to need at any one time. This is important for determining the inverter size (which converts DC electricity from the turbine to AC).

Example:

- LED Light (10W) – 6 hours/day = 60 Wh

- Refrigerator (150W) – 8 hours/day = 1200 Wh

- Laptop (50W) – 2 hours/day = 100 Wh

- Total Daily Energy Need = 1360 Wh

It's also wise to add a safety margin of 20-30% to your calculations to account for inefficiencies and future expansion. Consider how you're going to store this energy as well; energy storage, typically in the form of batteries, is vital for consistent power delivery. You can learn more about maximizing energy storage and battery selection to ensure your system runs reliably, even when the wind isn't blowing.

2. Wind Turbine Power Curve and Capacity

Wind turbines don't produce their rated power all the time. They have a 'power curve' that shows how much power they generate at different wind speeds. This curve is typically based on a specific rotor diameter and a standardized set of conditions.

Rated Power: This is the power the turbine produces at a specific wind speed (usually around 11-13 meters per second or 25-30 mph). It's a useful benchmark but shouldn't be your sole consideration.

Cut-in Speed: This is the minimum wind speed at which the turbine starts generating power. Below this speed, the turbine produces little to no electricity.

Survival Speed: This is the maximum wind speed the turbine is designed to withstand. Exceeding this speed can damage the turbine.

3. Calculating Turbine Capacity

To determine the appropriate turbine capacity, consider these factors:

- Average Wind Speed: This is crucial. You need to know the average wind speed at your location. You can find this data from local weather stations, online wind maps, or by installing an anemometer (wind speed meter) to collect data over a period of time.

- Capacity Factor: The capacity factor represents the actual energy produced by the turbine over a given period, as a percentage of its rated power. Capacity factors for small wind turbines are typically low, ranging from 15% to 40%, depending on wind conditions.

- Formula:

Required Turbine Rated Power = (Daily Energy Needs * 1000) / (Capacity Factor * Hours per Day)

Let's assume:

- Daily Energy Needs = 1360 Wh

- Capacity Factor = 25% (0.25)

- Hours per Day = 24

Required Turbine Rated Power = (1360 * 1000) / (0.25 * 24) = approximately 2267 Watts (2.27 kW)

Therefore, a 2.5 kW turbine might be a good starting point. Building a turbine is an exciting endeavor, and sometimes it can be a great learning opportunity for students and enthusiasts. You may even consider a small-scale wind turbine for a science project to understand the principles of renewable energy firsthand.

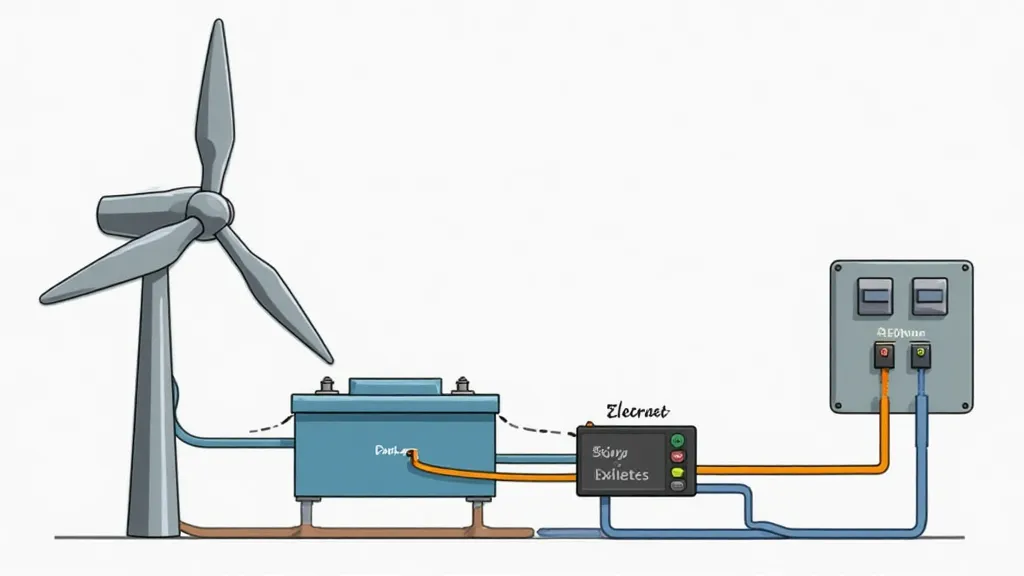

4. Turbine Components and Construction Details

Beyond the core power calculations, understanding the various components of a wind turbine and the materials used to construct them is vital. The choice of materials drastically affects performance, durability, and cost. For example, the blades are the most crucial part, responsible for capturing the wind's energy and converting it into rotational motion.

Consider the material used for the blades. Wood is a traditional choice, offering advantages like ease of shaping and relatively low cost. However, it's susceptible to weather damage and requires regular maintenance. PVC is another option, being lightweight and resistant to corrosion, but it can be less efficient than other materials. Fiberglass offers a good balance of strength, durability, and efficiency. You can read more about choosing the right wind turbine blade material to make an informed decision.

5. Safety Considerations & Regulations

Safety should always be paramount when working with wind turbines. Besides the mechanical risks associated with construction and maintenance, electrical safety is equally important. Proper grounding and wiring are crucial to prevent electric shock. Moreover, understanding local regulations and obtaining necessary permits is essential before embarking on your wind turbine project.

6. Advanced Optimization Techniques

Once your turbine is operational, continuous monitoring and optimization are key to maximizing energy production. Factors like tower height, blade pitch, and yaw control significantly impact performance. Taller towers generally experience higher and more consistent wind speeds, leading to increased energy capture. However, taller towers are also more expensive and require more robust foundations. Proper yaw control ensures the turbine is always facing the wind, while adjustable blade pitch allows for fine-tuning energy capture at different wind speeds. Always prioritize safety first in wind turbine construction and operation precautions.

7. Long-Term Maintenance and Troubleshooting

Like any mechanical system, wind turbines require regular maintenance to ensure reliable operation. This includes lubricating bearings, inspecting blades for damage, and checking electrical connections. Unexpected noises or reduced power output can indicate underlying problems that need to be addressed promptly. Proactive maintenance can extend the lifespan of your turbine and prevent costly repairs.